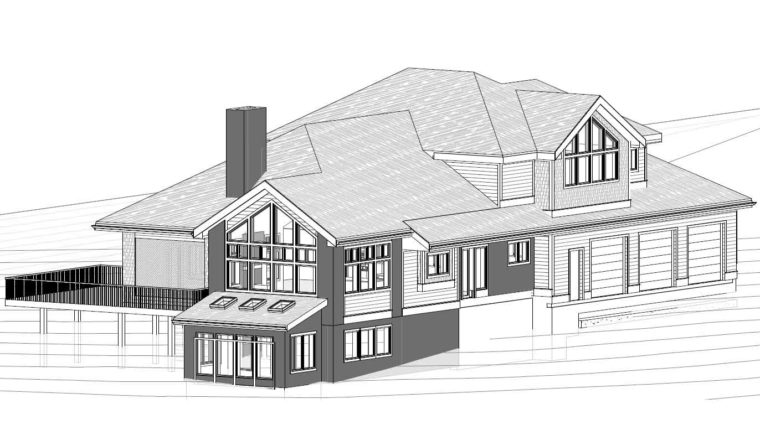

We first introduced you to this Des Moines custom home project in Project in Progress: Planning a Not-So-Big Custom House. Our clients purchased an old house on a great plot of land, but it was not feasible to renovate the existing building. They asked us to design and build a not-so-big custom home for them. The old house must come down first, and then we can start building the bones of the new one.

How exciting it is to watch the magic of construction begin!

I am not sure who was more excited — the family or us — when we saw the demolition crew arrive on site. It took less than half an hour to remove the existing home. With skillful maneuvering and experience the demolition crew kept the debris very contained and organized. This technique made a significant difference for sorting and loading up the materials before hauling them to the recycling station.

Once the house was torn down and the demolition materials sorted, we quickly moved on to the next phase. The clean ground was staked by our surveyor and prepared for excavation. The goal was for the new concrete footings and walls to be poured before winter temperatures arrived.

Weather Beacon Red, Warmer Weather Ahead

Weather is our most significant challenge when we’re dealing with the wet process of concrete work. It was very important for our team to deliver a high quality product. Because the foundation of a home is a very significant structural element, we were not making any compromises.

We had to extend the schedule slightly to hit the appropriate temperatures. Such adjustment allows for quality work in placing the formwork and also provided enough warm days for the concrete to cure. Our subcontractor follows The Weather Channel rigorously and we trusted his professionalism and expertise to accomplish this goal. During the formwork phase, it was impressive to see such a well-oiled machine – everyone had a task, the team was focused and precise, as the forms were erected.

Excavation of the house required an over-dig, making the footprint appear larger than the actual house. This is a necessity to ensure proper footing construction and slope retention.

Ground work is a rough and dirty stage of new home construction and can include wet soil, sticky mud, wet concrete and black liquid waterproofing. Site visits at this phase are always amusing for the design team – if you want to walk around the building you better put your mud boots on.

Once the concrete walls were properly cured, and waterproofing and exterior drainage was installed, we moved on to backfilling. This is the stage where the house outline takes a tighter form and the illusion of size is corrected.

Putting the Pieces of the Puzzle Together

In the following weeks our crew was busy erecting the basement floor walls and laying out the floor deck of the first floor. One board at a time, the pieces are fitting perfectly together to compile our framing puzzle.

Wood studs are shaping walls, walls are shaping rooms, and floor joists are shaping the main level of this custom new home.

Here we’re seeing the real view, and space proportions, as the custom new home building process progresses.

Still, there is a lot of work ahead. More framing elements are to be nailed together, more spaces are to be defined. It is joyful to see how careful planning has led to placing this new home in its appropriate location, thus providing strategic views from the interior towards the nature outside. There is a great joy in seeing the skeleton of this custom new home completed as we move on to its final beautification.

Up next? Framing the first and second floors, sheathing the house and setting the roof trusses to form the roof is our next exciting stage. Stay tuned for the next reveal of this not-so-big custom new home where we will show you more details and share the use of continuous exterior insulation for better thermal performance of the building’s shell.

View photos of another custom new home built by Silent Rivers »